Fixture technology

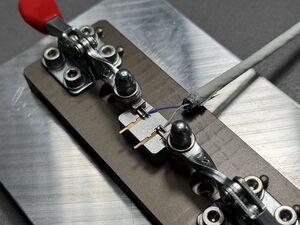

Process development begins in the laboratory. This is where the basic feasibility is analysed - for example, whether two materials can be welded together.

However, this initial statement is often not enough. The product should not only be welded in the perfect laboratory environment, but also under conditions as close to series production as possible.

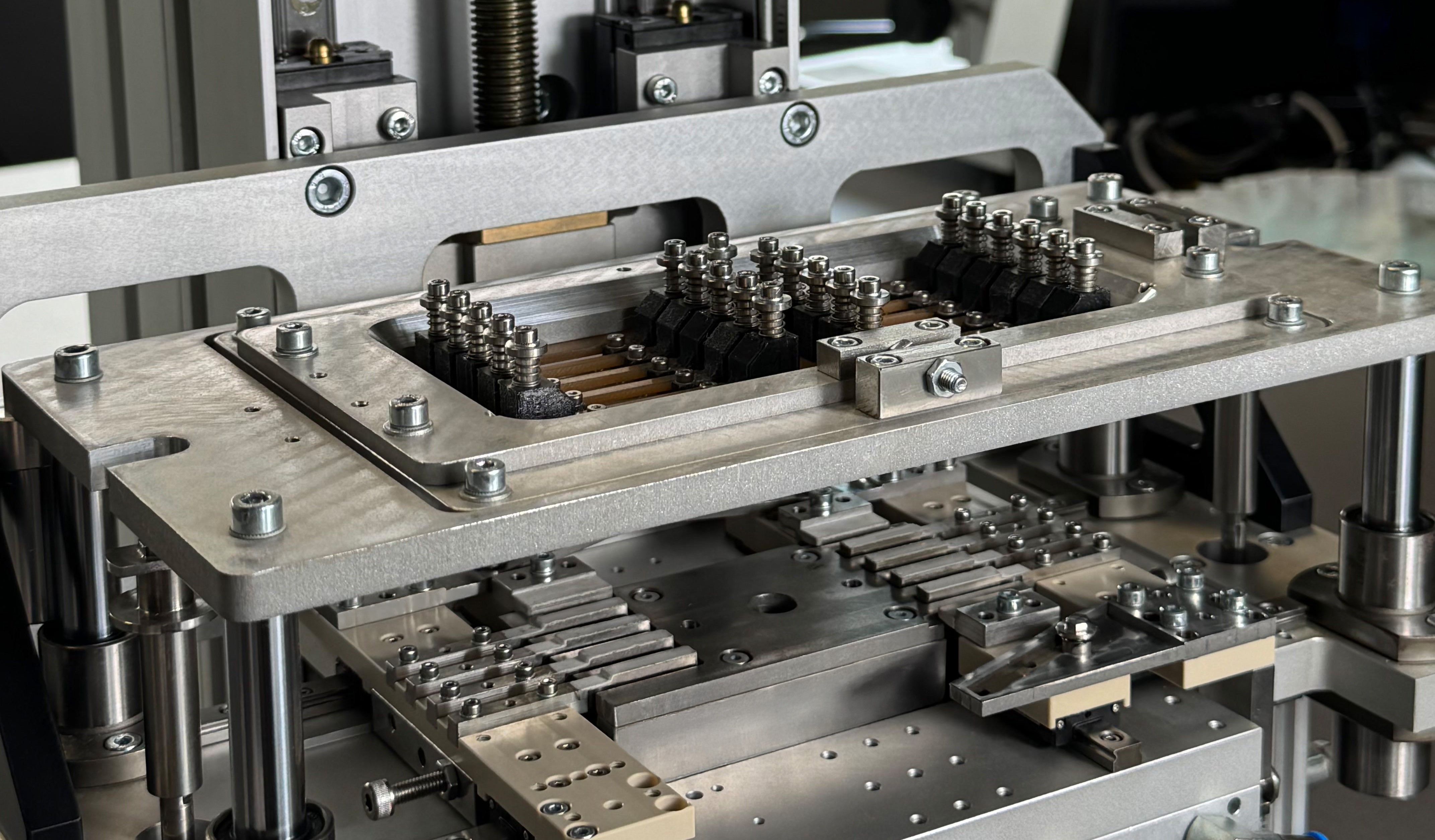

The key to success: fixture technology close to series production

A suitable product fixture forms the foundation for a stable and reproducible process right from the test phase. Reliable results can only be achieved with a clamping concept that is close to series production. A well thought-out, precisely manufactured clamping device reduces the risk of later problems in series production.

Customised - developed precisely for your product

We work with you to develop a fixture that is precisely customised to your components and process requirements. The fixture compensates for tolerances in the product and creates reproducible, near-series conditions. This allows realistic and transferable test results to be generated. Risks can be recognised and eliminated at an early stage. Optionally, pneumatic movements or sensors can be integrated into a test device.

Thanks to our decades of experience in laser material processing, we know what is important and how a suitable clamping device must be designed. We develop, design, manufacture and assemble your fixture in-house. You receive the finished fixture and all associated data (e.g. CAD models) - for maximum transparency and flexibility.

We optimise your device together in an iterative process. Findings from the test flow directly into the development of the series device.