Laser plastic welding

In plastic welding, the parts to be joined are usually overlapped and beam welded. With this overlap welding, weld strengths in the order of magnitude of the base material strength can be achieved with very small melting zones and low energy input.

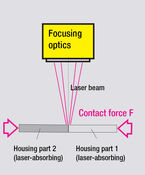

With this method, the laser beam shines through the upper joining partner and is absorbed on the surface of the lower joining partner. This leads to melting of the absorbing partner. The laser-transparent joining partner is also melted locally to a very limited extent due to the surface contact of the parts pressed together.

If the joining partners are pressed together appropriately, the thermal expansion of the melt, which can be up to 30%, causes mixing of the molecular chains in the melting zone. In butt joint welding, both joining partners must be equally laser-absorbent. The joining partners are specifically heated at the seam by the laser beam and material is melted. Appropriate contact pressure is also required here.

The upper joining part (facing the laser beam source) must have a low absorption rate for the radiation of the lasers used. The transmission should be above 60%.

Most plastics are laser-transparent in their raw state. Glass fibers reduce the transmissivity. If the overlying joining part is to be colored, appropriate laser-transparent pigments must be used. n n n Appropriate pigment formulations are available on the market today. Laser-transparent black colorations are easily possible.

The joining part underneath should be laser-absorbent. The laser radiation should be able to penetrate up to a maximum of 0.3 mm. This is most easily achieved by black coloring with carbon black particles. However, other laser-absorbing colors are also possible. By applying an additive in liquid form, laser-transparent material can be made laser-absorbent on the surface and is therefore also weldable.

Laser applications

The laser beam can be applied to the workpiece in different ways:

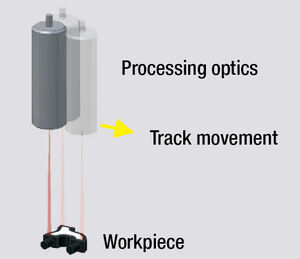

In contour welding, a focused laser beam is moved once along the welding path. The size of the focal spot corresponds to the thickness of the weld seam. Contour welding places high demands on the evenness of the welding surfaces. The gap dimension must not exceed 0.1 mm.

Advantages:

- Low beam quality requirements

- Low laser power is sufficient

With simultaneous welding, the shape of the laser beam is adapted to the weld seam. This eliminates the need to move the laser beam along the welding path. This process is recommended for geometrically simple welding contours, such as lines or circles.

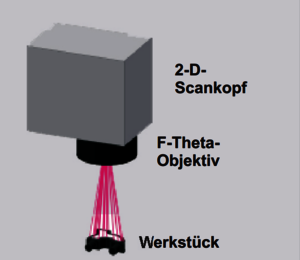

In quasi-simultaneous welding, the focused laser beam is moved over the welding path in short cycles so that the entire welding path is heated evenly. If the laser beam is moved via scanner mirrors, geometrically complex welding contours are also possible.

Advantages:

- Process monitoring possible by measuring the setting movement

- Low demands on the welding surfaces due to welding output

- Short process times possible

Welding of rotationally symmetrical parts

When welding rotationally symmetrical parts, the workpiece can be rotated in the simplest case.

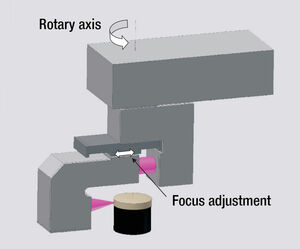

The Wolf rotation optics (see image) enable a radially rotating laser beam. The workpiece can be stationary. Alternatively, the rotation optics can be set up for an axially rotating laser beam.

The focal point of the laser beam can be changed using an adjustment slide. This makes it possible to weld workpieces with different diameters.