Skyline

SkyLine®

The process technology of the individual laser processing methods can be integrated into customized machines. Wolf's SkyLine® platform is available for this purpose.

The SkyLine automation platform is the basis for everything from stand-alone systems to complete transfer lines consisting of several production modules (automatic modules or manual workstations). Production modules can contain several modular stations, which can be designed to be quick-changeable if required. The hardware and software structure is also consistently standardized. SkyLine® stands for both to a high degree:

- Conversion flexibility

- Conversion flexibility

The typical workpieces fit into a shoe box, have high quality requirements and are produced in large quantities > 200,000.

Dimensions

The standardized machine technology offers a range of size options, allowing a choice of widths from 800mm to 2200mm and depths from 1000m to 2200mm. With this flexible modular system, tailor-made special machines can be realized. The process technology for most laser processing methods can be accommodated in an AM 100 cell with a width of 1000 mm and a depth of 1000 mm.

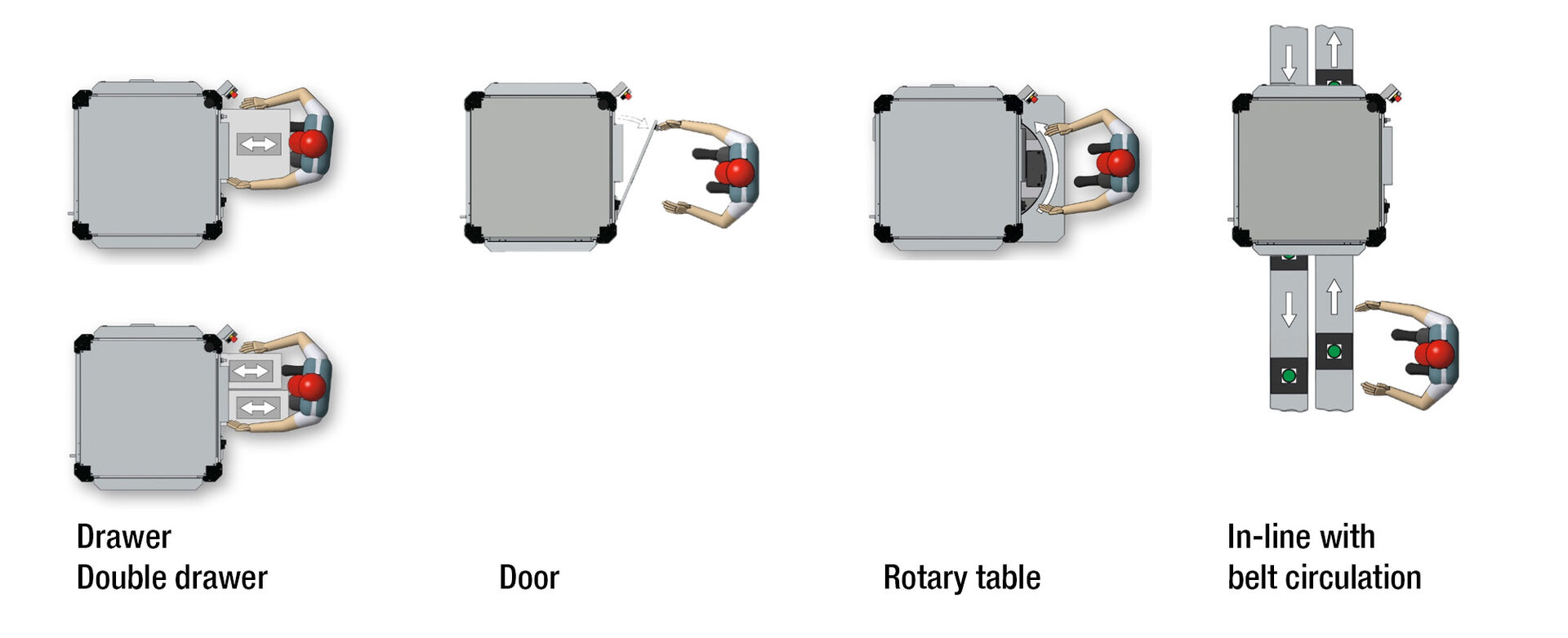

Workpiece feed

The workpieces can be brought into the work area as follows:

- Doors

- Pendulum drawers (single or double), motor-driven

- Rotary indexing table, motor-driven

- Double belt conveyor (In-Line)

Interlinking is possible for SkyLine automatic modules (cell). In assembly lines, the workpieces are transported on workpiece carriers. These are moved into and out of the cells on an in-line double belt conveyor.