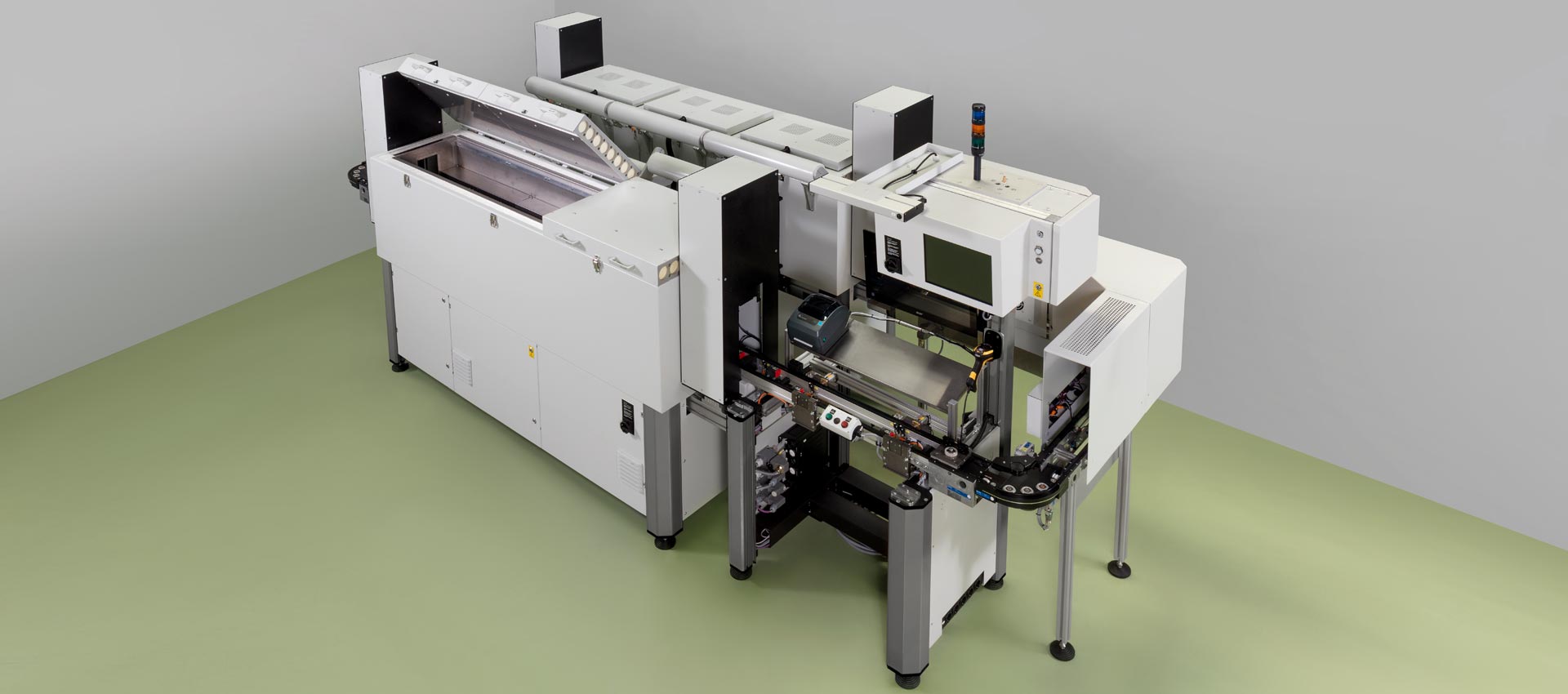

Assembly line for sensors

A sensor, also known as a detector or probe, is a device for recording physical or chemical properties. These include temperature, pressure, light, acceleration or the material properties of the environment and much more.

Active sensors usually consist of a measuring element and electronics. The element detects the desired property. The electronics convert the signal into an electrical signal. This signal can then be processed by a control unit to control certain functions.

In addition to sensors, actuators also play a central role in automation technology. Actuators convert electrical signals into movements. They enable targeted control processes.

Read more about the automatic assembly of actuators here.

Sensors can be found in many everyday objects today. They are an essential component of modern technologies.

Some examples are

- Temperature sensor

- pressure sensor

- Speed sensor

- Steering angle sensor

- Displacement sensor

- Rain sensor

The typical structure of sensors is often similar.

Wolf Produktionssysteme has almost 30 years of experience in the development and manufacture of machines for sensor production. With comprehensive process know-how and a deep understanding of the technology, we realize precise and efficient manufacturing solutions.

Typical sensor production processes

Several steps are required to manufacture a sensor. These vary depending on the design of the component. Common processes are

- Automatic joining of components (e.g. printed circuit board)

- Hot caulking

- soldering

- Potting

- Curing the potting compound under defined ambient conditions

- Automatic optical inspection (AOI)

- Calibration of the sensor (adjustment, alignment)

- Plastic welding with laser

- Laser marking

- End-of-line testing (EOL)

In order to automate production, the individual parts must also be fed automatically to the production line, e.g. by the TrayLine palletizing system

Adjustment / calibration

Sensors only deliver precise measurement results if they are optimally adjusted. As minimal deviations occur during production due to manufacturing tolerances or material properties, the sensor is adjusted after production.

Typically, the adjustment is carried out by comparative measurements with a reference value. The sensor is placed in a defined environment, measures a known value and adjusts its output signals accordingly. Adjustment is therefore a central component of sensor production.

When adjusting temperature and pressure sensors, our ThermoLine systems set a constant temperature. The decisive advantage: the systems can be integrated directly into flow production. Adjustment is fully automatic - with complete traceability at all times. In addition, test or calibration stations can be integrated directly into the thermal section, for example.

Would you like to find out more?