Why do you need preheating?

Preheating is necessary or useful for some manufacturing processes. Preheating is often used for soft soldering. This makes the subsequent soldering process faster and of higher quality.

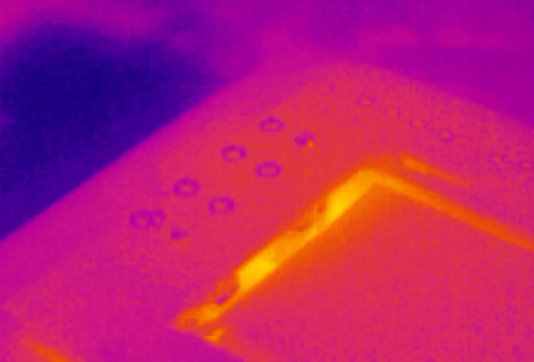

Preheating with a laser

Preheating with a laser is very efficient, as energy can be applied with pinpoint accuracy for heating. The radiation is very homogeneous and the power can be precisely controlled. Surfaces that must not be heated can easily be covered with masks.

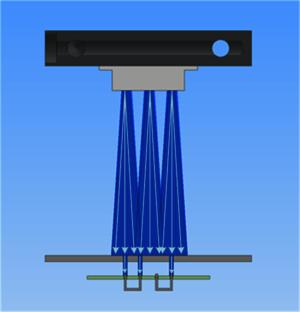

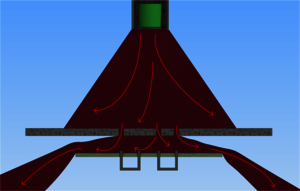

Preheating with hot air and heat recovery

In conventional preheating processes with hot air, cold ambient air is drawn in, heated in an electric hot air blower and then directed onto the workpiece. By encapsulating the preheating station, the already heated air that has flowed past the workpiece can be fed back into the hot air blower. This requires special hot air blowers that can draw in both cold and warm air. Depending on the application, considerable energy savings can be achieved through this heat recovery.