Special soldering technology

Special soldering

Solder joints are conductive and material-locking.

The process temperature, i.e. the soldering temperature, is far below the melting temperature of the materials.

This is why soft soldering is the dominant joining technique in electronics.

The choice of the optimum soldering process is crucial. That is why we have acquired the "know-how" in all essential special soldering processes.

Not only in theory but also in practice.

We have demonstration machines in our Tec Center available for each soldering process with which we can carry out soldering tests for your tasks.

Laser soldering

Depending on the application, we use a single laser source or our SIXPACK - a laser soldering head with up to six independently controllable diode lasers. We work with different wavelengths, customised optics and optional beam movements to enable good energy input. This allows us to find the optimum process for your product, even with varying solder joint geometries or sensitive components.

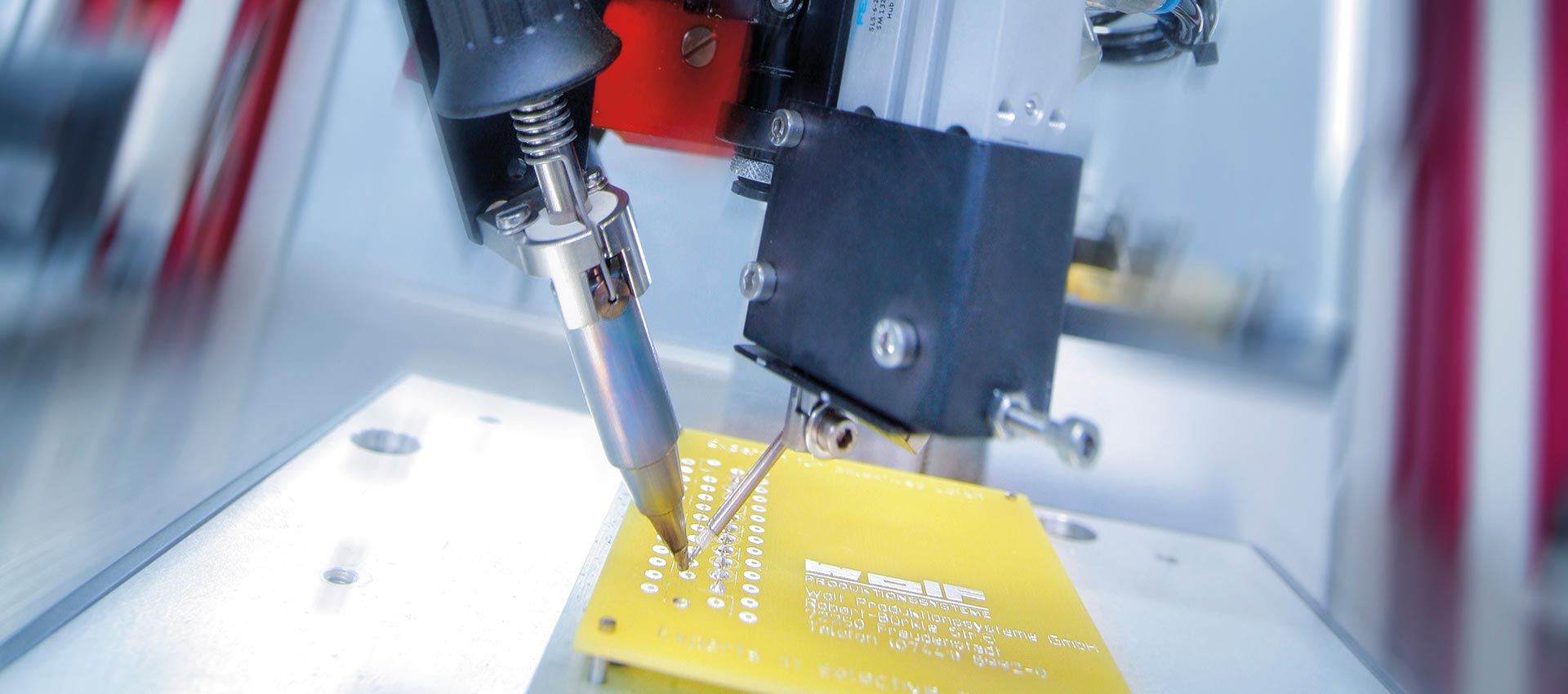

Automatic iron soldering

Iron soldering as a tool for soft soldering has been state of the art for decades. This process can be automated taking into account important criteria.

Induction soldering

The principle of HF-induction heating is that a one or multi-turned coil (inductor) is lived by an alternating current of high frequency. This inductor builds in its vicinity an alternating electromagnetic field.

Miniwave soldering

There are still PCBs with SMD parts and wired components which need to be soldered. Selective soldering with miniwave offers itself especially for large quantities of solder joints.

Selective soldering with stroke-dip process

Wired components still need to be soldered into SMD-equipped PCBs. Lift/dip soldering is particularly suitable if the solder joints are distributed across the PCB.