Induction soldering

The operating principle of HF induction heating is that an alternating current flows through a single or multi-turn working coil (inductor). This inductor builds up an alternating electromagnetic field in its environment.

If an electrically conductive workpiece is placed in this alternating electromagnetic field, a voltage is induced in it, which generates an alternating current. According to Joul's law, heat is then generated in the surface area of this workpiece through which the current flows.

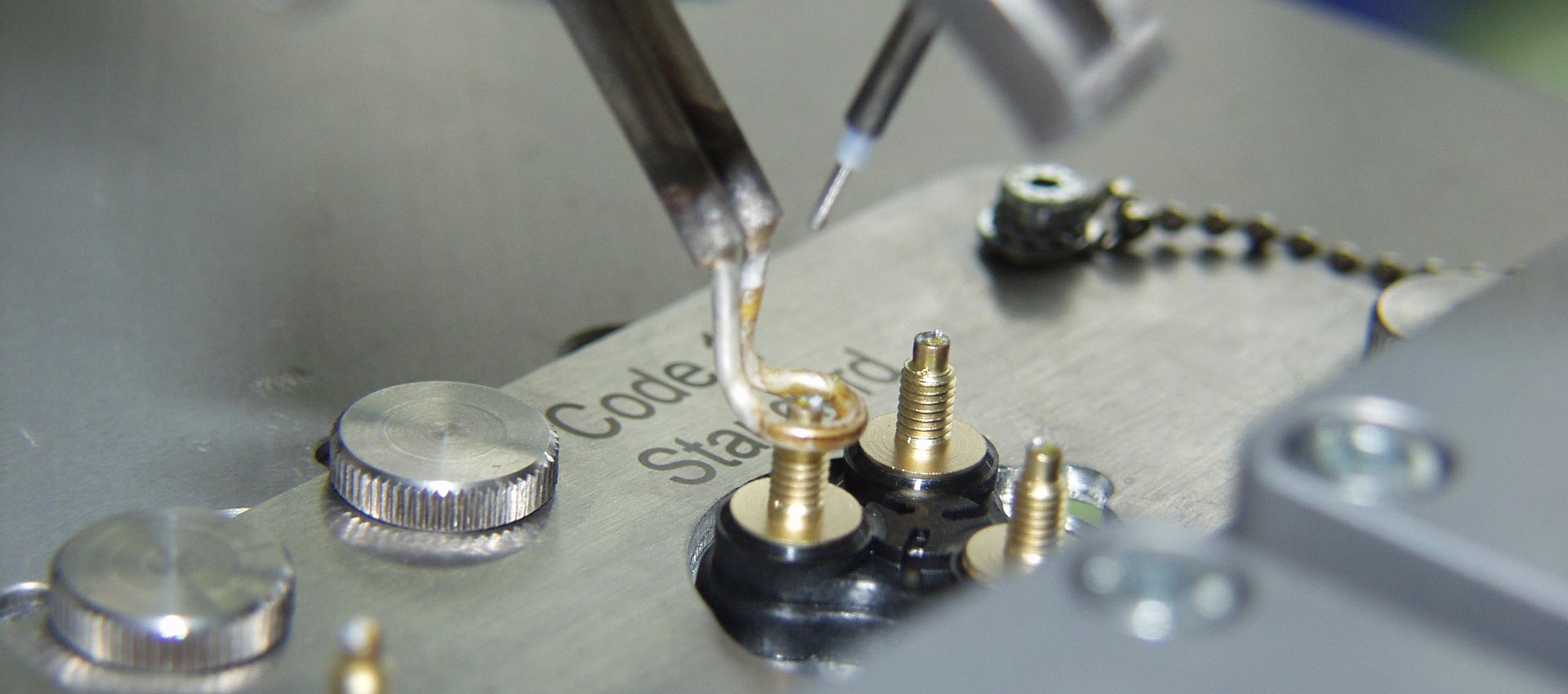

The coil, called an inductor, must be water-cooled. Galvanic isolation ensures maximum safety for operators. The inductor can be easily adapted to a wide variety of solder joints. In practical terms, an induction system works according to the transformer principle, whereby the inductor is the primary winding and the workpiece is a single-winding secondary winding.

Induction soldering is a safe process and a robust soldering method. However, because of some restrictions its implementation is limited. For suitable products induction soldering is an “ideal” soldering method due to very good through heating of the solder joint - like the part was heated from its inside.

We gladly offer our advice for your project and for any soldering tests our demonstration machines in our Technology Centre are at your disposal.