Selective soldering

Miniwave soldering

There are still PCBs with SMD parts and wired components which need to be soldered.. Selective soldering with miniwave offers itself especially for large quantities of solder joints. Miniwave can be used from a free space of 2mm around the solder area. Owing to quick changeable nozzle sets this process is flexible and can be applicable for varied solder joints. Also tin coating of copper strands, as well as skinning of lacquered wires is also possible in miniwave.

Selective soldering derives from wave soldering with which the solder area is restricted due to reduction of the solder wave and reducing the soldering bath size to smaller solder nozzles.

Principally, it can be differentiated between “dragging” and “dipping” the work piece in liquid solder.

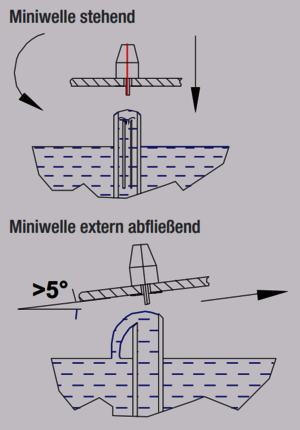

Dipping means that the work piece is dipped in a “stationary” miniwave. In order that the emerging oxide film breaks away at the surface, the solder wave runs inside of the nozzle. In order to reduce oxide formation on the nozzle orifice and to improve the soldering, the nozzle is bathed with nitrogen.

Selective soldering systems can be constructed as fully automated machinery in “in-line-models” or as hand assembly workplaces. Basis is the Wolf Standard Module (see separate production information Production Module)

We offer our support with the process development and offer the possibility of soldering and preproduction series tests in our Technology Centre.

Principle

Selective soldering is derived from wave soldering. While in conventional wave soldering the entire PCB is soldered, in selective soldering only defined areas should come into contact with solder.

Selective soldering can be divided into two processes:

Process flow

1. application of flux (spraying, dipping or flux jet)

2. preheating (hot air, radiators)

3. soldering (internal or external mini wave)

The workpiece is immersed in a “stationary” mini wave. In order to tear off the resulting oxide skin on the surface, the solder wave flows inside the nozzle, i.e. internally. This prevents the solder from cooling at the nozzle outlet during soldering. To reduce oxide formation at the nozzle outlet and improve soldering, the nozzle is flushed with nitrogen.

The circuit board is dragged over a mini-shaft against the flow direction of the solder. This allows a larger area to be soldered on a PCB. To avoid solder bridges between two neighboring solder joints, the solder must “break off” in a defined manner. For this purpose, the circuit board is dragged at an angle greater than 5°. To reduce oxide formation at the nozzle outlet and improve soldering, the nozzle is flushed with nitrogen, as with the standing mini wave.

Application

Wired components still have to be soldered into SMD-assembled PCBs. Selective soldering with a mini wave is particularly suitable for a large number of solder joints. Miniwaves can be used from a free space of 2 mm around the soldering area. Thanks to quick-change nozzle sets, the process can be used flexibly for a wide variety of solder joints. The tinning of stranded copper wires and the stripping of enameled wires is also possible in mini waves.