Concepts

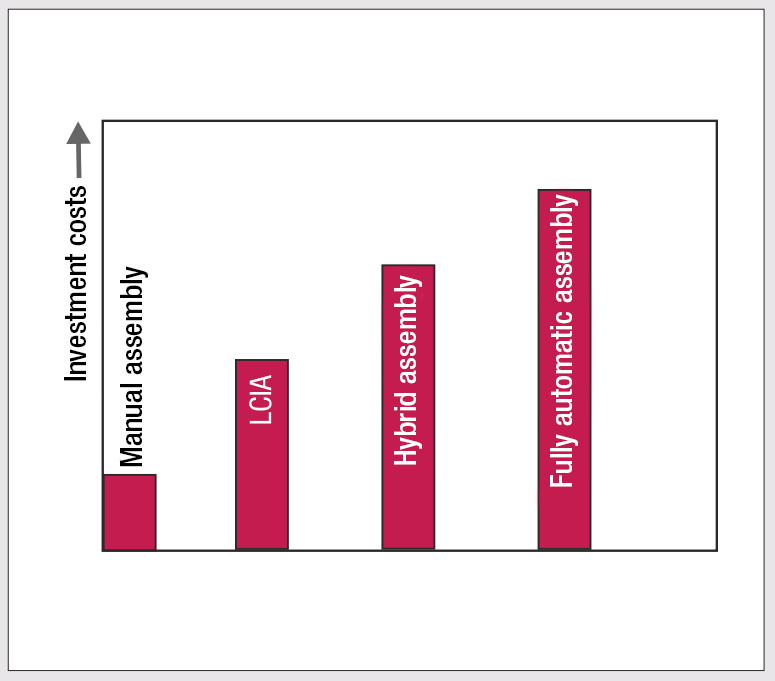

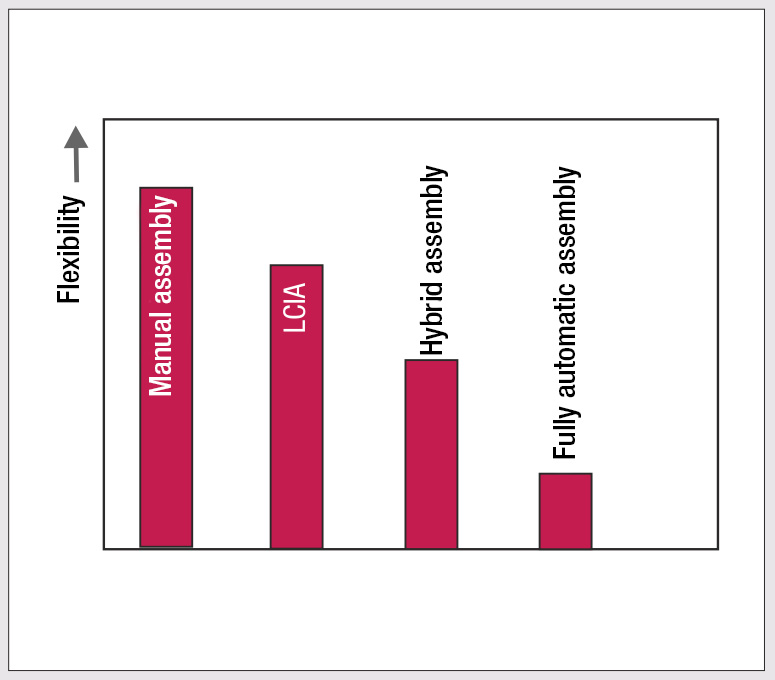

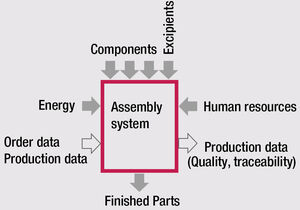

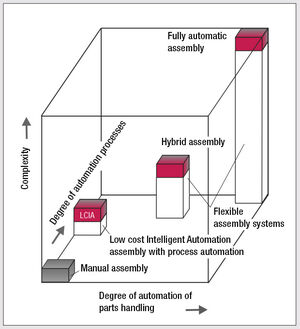

Maximum quality and productivity in production can be achieved with the automatic assembly of products. This is offset by high investments. It is therefore important to plan customized systems with an optimum degree of automation. The planning of a customized assembly system starts with the basic decision on how to transport the parts.

Wolf Produktionssysteme offers the following options:

The principle

Overly complicated, expensive assembly systems are the result of so-called “overengineering”.

Here, the degree of automation, system management, traceability, component diversity, design and control technology are not adapted to the task at hand. Wolf Produktionssysteme is responding to the trend towards simpler, flexible assembly systems and offers hybrid assembly systems and LCIA assembly lines in addition to complex, fully automated assembly lines.

Wolf consistently focuses on:

- Specialization

- Standardization

Assembly lines Become strictly modular, composed of self-sufficient, standardized production modules. Built for sophisticated products. Standardization enables an exact description of the assembly system right from the quotation stage. The result is investment and costing security.

Added to this is the need for “simultaneous engineering”, conversion and modification flexibility, maximum availability and ease of operation. Finally, embedded in an individually appealing design in terms of color and surface.