Wolf TrayLine System

With the TrayLine, Wolf Produktionssysteme offers an innovative system for the automatic infeed and outfeed of small parts on pallets. The system impresses with its cost efficiency, modularity and flexibility.

During automatic operation, pallets can be removed or inserted at any time without interrupting machine operation. The TrayLine can be designed for pallets of different formats. The pallets are moved individually to achieve maximum precision and accuracy. Thanks to its high level of standardization, the TrayLine is particularly cost-effective and can be expanded modularly to increase the storage capacity and thus the autonomy of the system.

The TrayLine system can be used both as a palletizer and as a depalletizer.

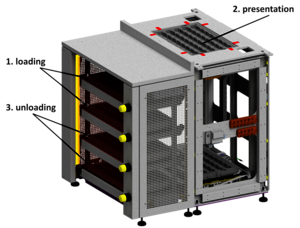

TrayLine Base

Functionality for feeding components (depalletizing)

1. loading:

2. presentation:

3. unloading:

The system can be extended horizontally and vertically and adapts flexibly to your requirements.

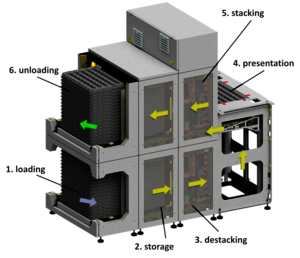

TrayLine Stock

The TrayLine Stock extends the functions of the TrayLine Base by adding the option of stacking and destacking pallets. This means that entire stacks of pallets can be fed in while the system is running, saving space.

Functionality for feeding components (depalletizing)

1. loading:

2. storage:

3. destacking:

4 presentation:

5. stacking:

6. unloading:

Additional storage modules can be used to increase the storage capacity and therefore the autonomy of the system.