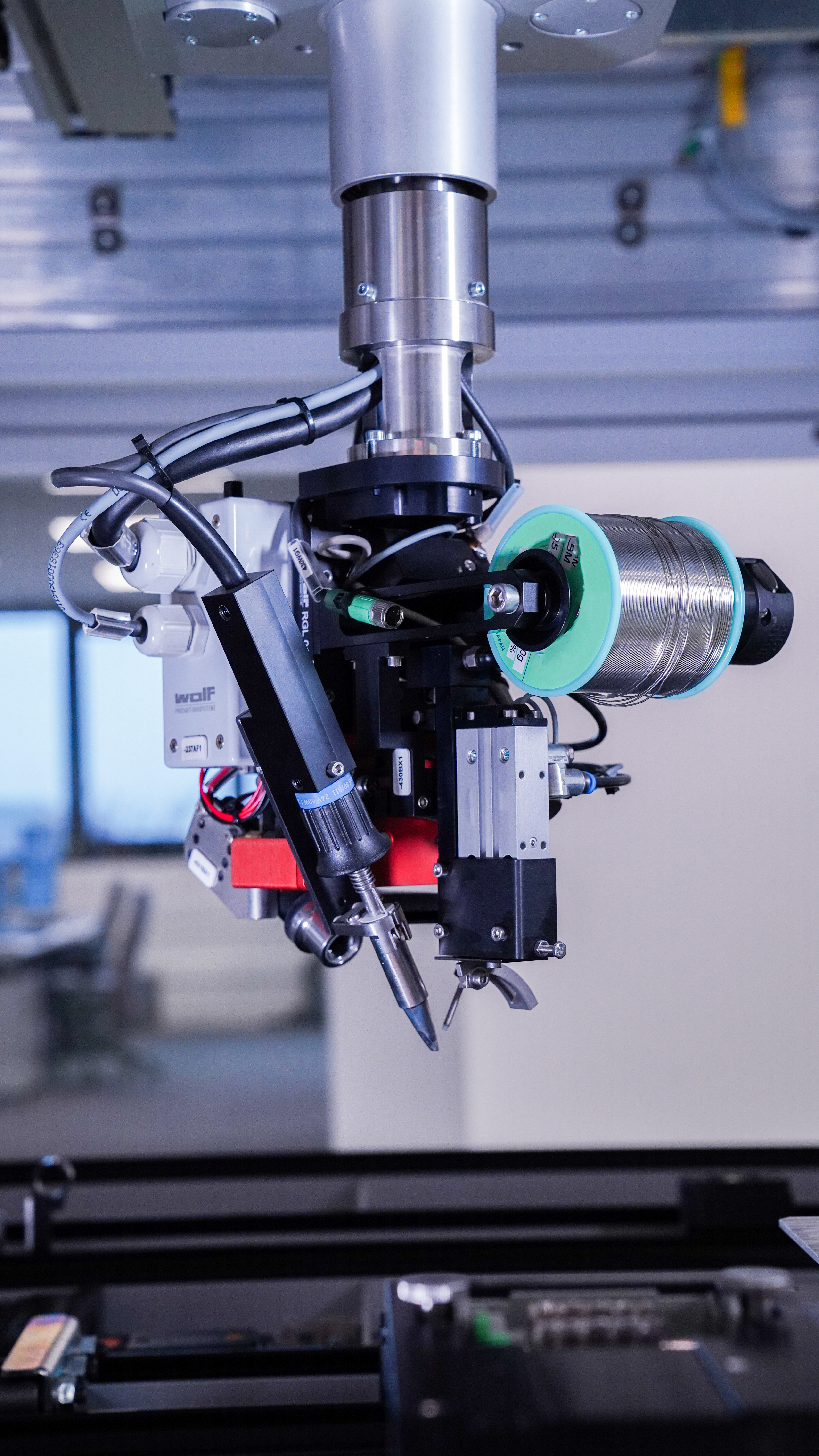

Automatic iron soldering

The soldering iron as a hand tool for soft soldering has been state of the art for decades. This process can be automated if important criteria are observed. One such criterion is pressing the soldering iron against the soldering point to ensure constant heat transfer.

Wolf has developed the patented Quick-Step process for this purpose. In piston soldering, the flux is supplied via one or more flux cores in the solder wire. The soldering point is heated via the soldering tip and the solder is fed to the soldering point. Automatic piston soldering is also suitable for solder joints that are difficult to access.

Application

Not all solder joints on printed circuit boards and other electrotechnical assemblies always allow complete soldering (wave soldering, reflow soldering). They must be soldered individually. With piston soldering, these soldering tasks can be

1. automatically and

2. reliably

be carried out reliably. By using handling systems with up to four programmable axes, piston soldering can be used flexibly and is suitable for a wide variety of soldering tasks.